Save the date

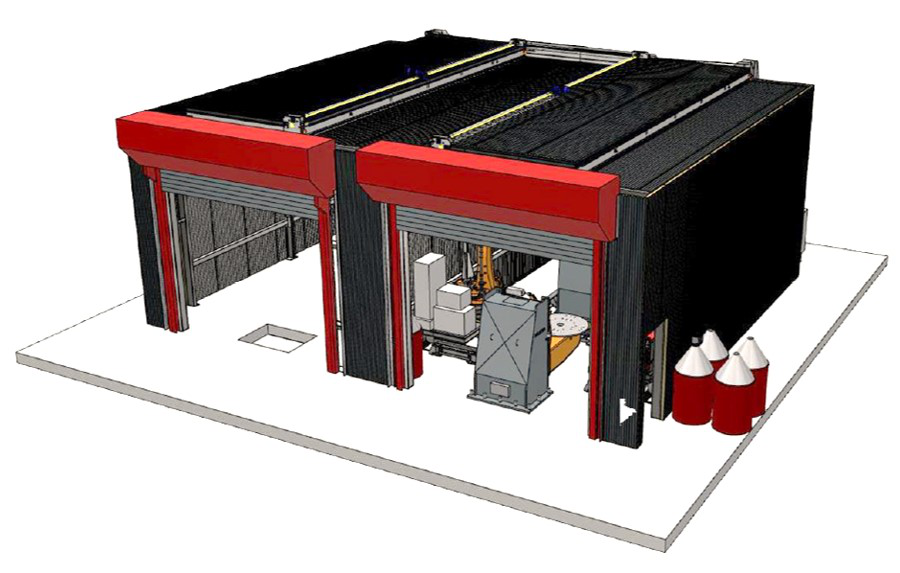

The brand new Guaranteed production facilities offers a unique value proposition

The most important value propositions of GUARANTEED can be summarized as:

- Cost efficiency: As the main focus of GUARANTEED will be on the repair or refurbishment of existing components rather than on full (re)design optimization, cost efficiency compared to conventional manufacturing is an important benchmark. Our choice of technology is characterized by (relatively) cheap hardware as well as consumables and running costs, while at the same time being industrially robust at high TRL level.

- Obsolete part repair: Single part obsolescence can bring forth huge costs associated with full system replacement. The repair of such parts can represent significant cost savings because the reason for obsolescence is often related to excessive wear or localized damage rather than full component failure. The GUARANTEED technology is currently the only technology which features this repair functionality.

- Sustainability: Components are often scrapped due to localized wear or damage. The repair of such components instead of the full reproduction, responds to rising societal concerns with regard to the availability of critical raw materials and energy. Therefore it perfectly fits into the concept of circular economy.

- Large scale: Given the nature of our target sectors, being able to handle large components (throughout the full production flow) clearly constitutes a competitive advantage.

- Performance optimization: Although GUARANTEED’s first focus will be on repair, opportunities for upgrading the component performance after repair is a much appreciated added value to our customers.

- Short lead times: Given the high deposition rate of our technology as well as its compatibility with conventional post-processing operations without posing additional safety hazards, we are able to meet our customer’s requirements of realizing short lead times.

- Guaranteed properties: Thanks to the process control software as well as the in-situ process control and non-destructive testing, we are able to overcome one of the main hurdles that have hindered further and more widespread adoption of the technology in the past, and which are related to ensuring the performance of the repaired component.

- Reduced logistic costs: Besides the direct cost benefit which can be achieved by repairing a damaged or obsolete component, there are additional benefits associated to e.g. stock-keeping or transportation.

- Industry 4.0: As our production tools will be fully instrumented and automated, they are future-proof and can easily be linked up to a more advanced digital approach.